CNC Turning Services &CNC Turning Parts Manufacturing

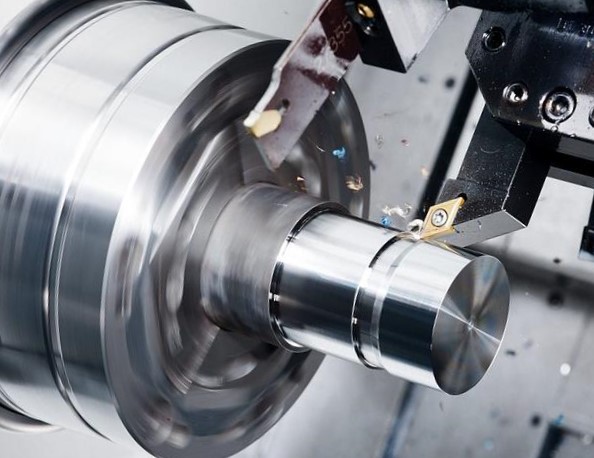

What Is CNC Turning Service?

CNC Turning Service is a machining process in which bars or pipes of materials are held onto a chuck and rotated while a tool is fed to the piece to remove material to create the designed shape. For cylindrical parts such as pins, shafts, and spacers, or parts with general rotational features, “CNC Turning Service” on them is usually the easy and most economical choice.

Since 2005, AS PRECISION has been providing superior CNC turning service. We offer a huge range of CNC precision machining capabilities with various CNC turning lathes that can be programmed to meet your exact specifications, no matter how simple or complicated the structure is. We offer CNC Turning services for your Prototype, Sampling, Trial Order, and mass-huge order. As we have long-term experience, you will get qualified CNC turning parts and satisfaction service from us at the soonest time with competitive prices.